Specialized shelf application +1

2020-11-20

Application of custom shelves and accessories

Our company provides specialized shelves and accessories that closely meet user needs, leveraging excellent design capabilities and years of practice.

Users can plan their logistics storage methods based on a simple introduction.

1: Examples of heavy-duty shelves made of section steel

|

|

User products may have many overweight, oversized, and other special-shaped goods or equipment, and using standard shelves will have many limitations. Our company designs and manufactures many custom projects using commercially available standard steel profiles to reduce the footprint for users. This shortens processes and has a very good effect. |

Key points for selection:

1. Whether lifting on site is done with a forklift or a crane. Different lifting methods have a significant impact on the design of the shelf group.

2. The weight, shape, access rhythm of the stored goods, and whether special brackets are needed.

|

Automatic warehouse for car shells of Beijing Benz |

ABB Beijing testing motor system rack |

Equipment installation rack for automobile factories |

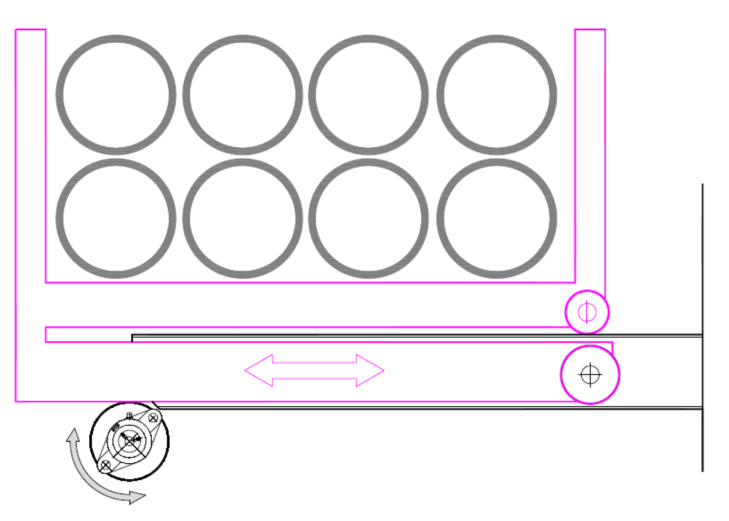

2: Movable cantilever shelves

|

|

|

|

Movable cantilever shelves are suitable for storing long materials and can be moved out electrically or manually for easy access by cranes. Reasonable layout of multiple movable cantilever shelves can save a lot of floor space. The load capacity, dimensions, and number of layers of the shelves can be designed and manufactured according to user requirements. |

|

3: Pull-out heavy material rack

Specialized shelf application +1

Tools and Implementation of Lean Production Management

General Service Co., Ltd.

Service Hotline

Address: Jingfu Line Transfer to Construction Branch Road, Zhongbei Town, Xiqing District, Tianjin

Telephone: +86-022-23796453

E-mail: gs@gstj.cn / lsx@gstj.cn

WeChat QR Code

Copyright©Tianjin General Service Co., Ltd.